News and media - press releases: Komtrax® provides the key for top-class rental management

KOMTRAX®, Komatsu’s advanced remote equipment and machine monitoring system, has become an indispensable tool for the management of an extensive fleet of capital equipment operated by Old Lady & Son Plant Hire (OL&S).

The KwaZulu-Natal-based company leases equipment primarily to the construction industry and recently extended its footprint into mining and quarrying.

KOMTRAX® gives operations managers and hire operators greater control over their operations by providing easy access to the information they need to manage their fleets every day.

“Wireless, secure and user-friendly, the web-based application places a wealth of information at the user’s fingertips so that they can enhance utilisation, minimise downtime and reduce operating costs,” says Komatsu Manager: Sales and Marketing Toshi Ohtsuka.

Areas in which KOMTRAX® delivers user support are wide-ranging and include parameters like equipment hours, average hourly fuel consumption, idling times, water temperature and fuel levels. Machine conditioning is essential, and the system provides users with regular updates on routine maintenance needs.

OL&S Plant Hire owner Dave Haines makes extensive use of KOMTRAX®, to the point where it is now an integral part of the operation.

“As our business is equipment rental, we are concerned with hours - the billable hours we charge our customers for the use of our machines Maintenance is a non-negotiable issue and we strictly observe the minor and major service procedures notified by KOMTRAX®. A short-term cost-saving gained by skimping on an oil change is nothing compared with the financial consequences of an expensive machine standing idle,” he says.

At OL&S, KOMTRAX® provides the data to support three vital functions: financial controls, engineering and maintenance, and marketing and costing. It enables the company to help customers optimise the efficiency of hired equipment and keep their costs under control, which has a direct beneficial effect on OL&S’s business.

In terms of operational costs, diesel consumption is by far his customers’ biggest consideration.

“They may have two identical excavators both working a nine-hour shift, but the operating costs can vary enormously. The first may be used for pipe laying and burn diesel at a rate of 13.4 litres per hour (l/hr). The second may be used for bulk earthworks and continually load trucks, which would likely consume fuel at a rate of 17.5l/hr. The difference of 4.1l/hr over a month of operations would equate to more than R10,000, which the customer must account for when costing operations,” says Haines.

KOMTRAX® data enables OL&S to better advise customers on anticipated fuel consumption relevant to their particular jobsite applications, thus improving their competitiveness when bidding for tenders.

The all-important energy saving report that comes with the company’s excavator models details actual operational hours as well as inefficiencies denoting idle time, times worked in power or economy mode, and light or heavy load applications. Every month-end OL&S sends this report to customers for each unit with advice how to improve machine utilisation.

Reporting daily fuel consumption based on injector volume, KOMTRAX® also enables OL&S to advise customers on the possible incidence of fuel theft by comparing fuel burn with volumes dispensed from diesel bowsers.

Furthermore, O&LS practice is to rent out each item of machinery with its own operator and KOMTRAX® offers the ability to monitor operator performance and habits. This functionality provides accurate productivity and utilisation information and can be used to elevate training for new and existing operators.

OL&S Plant Hire operations extend from the Eastern Cape right up to the Mpumalanga coalfields and KOMTRAX® provides the company’s team of dedicated mechanics with a huge amount of valuable information. This not only includes specific details and service requirements for the machines they maintain, but how to reach them.

Komatsu has a global contract with Google Maps which provides the exact location of each product, a major time saver when technicians go out to work on equipment in remote rural areas. Knowing exactly where machines are at any given time also discourages theft and unauthorised usage.

Haines’ final comment underlines the benefits the satellite technology has brought to his business.

“We wouldn’t even consider purchasing a machine without a tracking system as comprehensive as KOMTRAX® and our recommendation is that every plant hire manager should follow suit.”

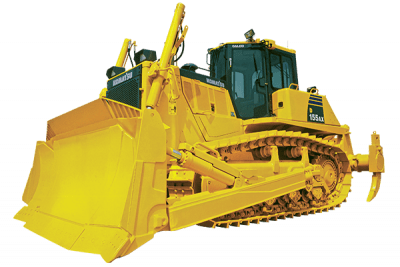

KOMTRAX® is now installed standard on every new unit of Komatsu construction equipment. The range includes excavators, dozers, wheel loaders, graders, rigid and articulated dump trucks. It can also be installed on equipment using 12v or 24v electrical systems which makes it possible to retrofit older Komatsu products or those produced by other original equipment manufacturers.

Users are able to access the system from their desktop computers and, more recently, via the KOMTRAX® ON THE GO App on their mobile phones.

Contact for further information:

KOMATSU SOUTH AFRICA (Pty) Ltd.

William Norton

Manager: Continuous Improvement & Aftermarket

Main Board +27 11 923 1000

Direct Line +27 11 923 1241

E-mail: william.norton@komatsu.co.za