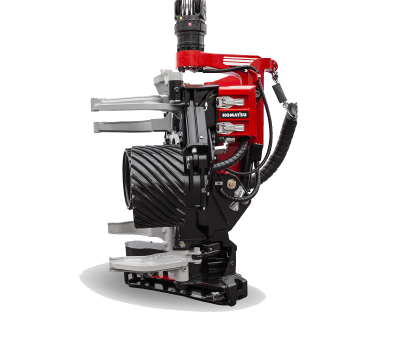

Undercarriage: Grouser shoe restrip

Komatsu South Africa’s track workshop facilities gives grouser plates new life by re-grousing them. This process is done by using a submerged arc welding process. Surfaces are prepared to ensure proper penetration of the welding process. The grouser plate is heated using an automated welding process to fit the new grouser bar to the existing plate.

Re-grousing is a value add and enables a cost saving to the customer and extends grouser shoe life.