Electric rope shovels: 2300XPC AC

Building on proven success

Mine operations and maintenance managers demand the best from their loading tools. For this reason, Komatsu Mining has been the electric mining shovel market share leader and preferred equipment supplier to the world’s toughest mining environments for over 100 years.

Komatsu is proud to offer the P&H 2300XPC AC electric mining shovel. The P&H shovel line is combining its solid reputation of reliability with the proven Centurion electrical control system, industry leading IGBT AC technology, rugged structures and the industry’s leading direct field service and support network to set the industry standard for electric mining shovels.

Increases in availability and productivity ultimately lead to the lowest cost per ton and the most efficient ultra-class loading tool available in the industry today. P&H shovels dig deeper into the realms of productivity, safety and reliability with greater control, comfort and consistency.

Specifications for 2300XPC AC

Overview

Powerfully practical

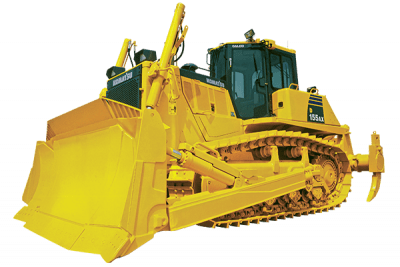

P&H 2300XPC combines the functionality of a high-performance rope shovel with the practicality of a smaller machine. Designed to operate in high production mines, this proven series of shovels are ideal for coal, copper, iron ore and gold mines around the world.

Up to 51% less CO2 release per tonne of material moved compared to eqv HEX machines.

12% lower cost per tonne of material moved compared to eqv HEX machines.

|

Height of cut |

13.5 m |

|

Radius of cut |

21.3 m |

|

Dumping height* (door open) |

8.5 m |

|

Floor level radius |

14.2 m |

|

Tail swing radius |

10.1 m |

|

Operator eye level |

7.9 m |

*Height shown with bail-type dipper. Heights will be greater with bail-less or compact-bail dippers.

Actual dumping height can be greater than door clearance height.

|

Nominal payload* |

45.4 mt |

|

Nominal dipper capacity/SAE struck |

18.3 - 25.5 m3 |

|

Optimum truck size (180 mt (200 st) truck shown) |

109 - 218 mt |

*Payload and dipper capacity are dependent on many factors.

Contact Komatsu Mining for an analysis of your specific application.

|

Supply voltage* |

4 160 or 7 200 V 3 phase, 60Hz |

|

Supply transformer |

(minimum) 2 750 kVA |

|

Minimum short circuit VA available at shovel |

22 MVA |

*Voltage per customer requirements.

Propel

Two rugged P&H planetary gear cases of proven design independently transmit torque to the drive sprockets, producing the tractive effort required for fast, efficient propel and positioning operations.

P&H brand Delta drive system with heavy duty cast crawler shoes.

Spring-set air release disc brakes – one per motor.

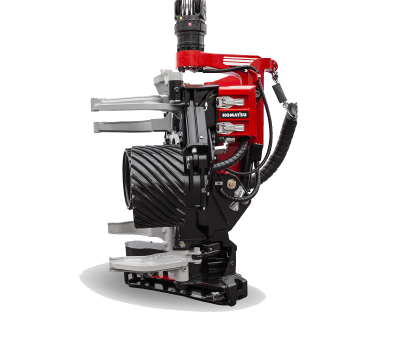

Crowd

Powerband V-belt drive between motor and gear case absorbs shock loads.

First and second reduction gearing in enclosed gear case for reliable splash lubrication, ease of maintenance, and extended component life.

Twin-leg dipper handle with torsion box and rack and pinion drive has inherent stability in the bank for optimal digging.

Spring-set air release disc brake.

Swing

Two modular P&H planetary gear cases of proven design and a single piece forged swing gear transmit torque for fast cycle times.

Spring-set air release disc brakes – one per motor.

Splash lube filtration system.

Hoist

All gearing housed in single enclosed gear case with filtered and cooled oil fed to all bearings in addition to splash lubrication for reliable operation and ease of maintenance.

Large 142.24 cm diameter hoist drum for extended rope bending life. Ferrule becket system and dual electric tuggers are standard for efficient rope change.

Spring-set air release disc brakes – one per motor.